Quality Management

Quality Policy

Quality Policy

- Achieve customer satisfaction through quality (accurately identify customer

needs and provide top-quality products on time) - Manage process defect rates (strict adherence to work standards and

thorough quality awareness training)

Quality Objectives

- Achieve a shipment inspection pass rate of over 95%

- Realize zero customer complaints (ZERO)

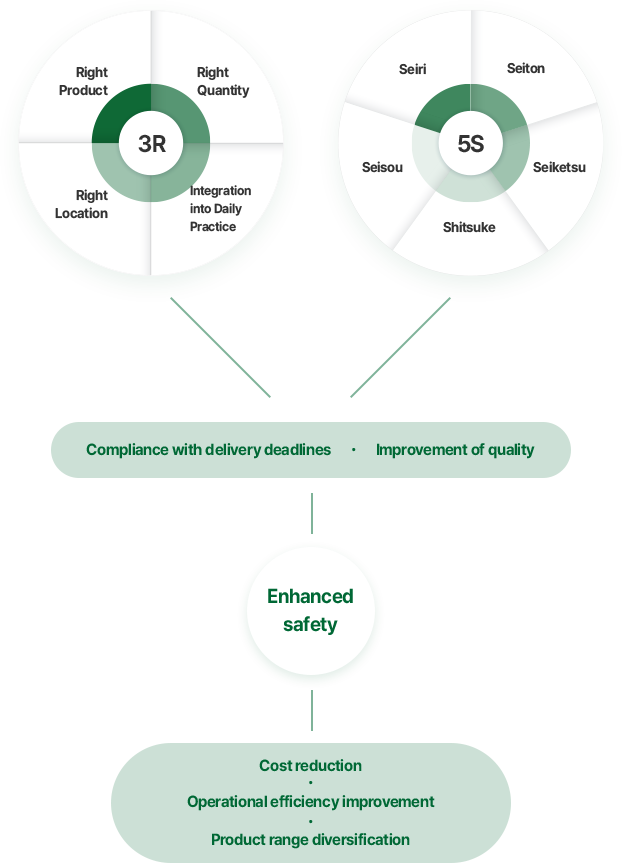

Implementation of 3R and 5S Activities

Definition of 3R and 5S

3R

-

Use materials or

Use materials or

components that meet

specified standards. -

Return items or tools

Return items or tools

to their designated

places after use. -

Utilize only the

Utilize only the

predetermined quantity

of materials or resources.

5S

-

Seiri

SortDifferentiate between necessary and unnecessary items,

and boldly discard what is unnecessary. -

Seiton

Set in OrderAfter sorting, arrange items so that anyone can easily

and conveniently access them when needed. -

Seisou

ShineClean the workspace and equipment by removing dust,

dirt, and foreign substances to ensure cleanliness. -

Seiketsu

StandardizeMaintain the conditions of sorting, setting in order, and

shining to create a hygienic work environment. -

Shitsuke

SustainIncorporate the concepts of 3R and sorting, setting in

order, shining, and standardizing into daily practices.